Partner Q&A Series 6

As we continue our Partner Q&A series, we chat with Jack from Crafton Constructions…

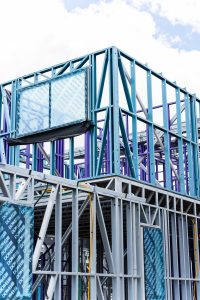

As Australia’s leading residential steel frame supplier, Aus Steel has seen considerable growth and success over the last few years.

This is due to its unrivalled industry experience and drive to always challenge the way we build.

As we continue our Partner Q&A series, we chat with Jack from Crafton Constructions…

Today we continue our Partner Q&A series with a catch up with Martin from Tempo Living. Today Martin tells us his firsthand experience working with AusSteel and AusSteel’s Ultimate Building System…

Today we continue our Partner Q&A series after a great chat with Tyler from Contessi Build. If you missed the first three posts in the series, be sure to check them out…..

And we are back with Part 3 of our Partner Q&A series! For today’s post we had a good chat with Mark at Prosperity Home about his positive experiences working with AusSteel and our Ultimate Building System…

Welcome back for Part 2 of our Partner Q&A series. Today we talk with Josh at Proformance Projects about his experiences working with AusSteel…

Welcome to Part 1 of our Partner Q&A series, where we chat with some of our esteemed partners and their outstanding trades, as well as other industry professionals about their experiences working with AusSteel. For today’s discussion, we spoke to Travis from ITI Building…

A very special day is just around the corner; Friday 30th of August is Jersey Day. AusSteel wholeheartedly supports Jersey Day, and here’s why we think you should too…

In our last post we looked at some of the common misconceptions behind builders’ hesitation to switch to offering steel framing solutions to their customers. In Part 2, we continue the conversation to help you navigate this often confusing phenomenon.

In recent years we’ve seen huge growth in the number of reputable builders offering the option of steel framing to their customers. And yet still, some don’t. We look at some of the misconceptions around switching to steel to which builders or trades may subscribe…

When building a home, it’s understandable that the soon-to-be new homeowners want to see their build completed as quickly as possible. It may then come as a pleasant surprise to home builders that building a house with a steel framing system like AusSteel’s #ultimatebuildingsystem can be a quicker process than building a timber-framed home.

Unless you’re new around here, by now you would be aware of just how hard we at AusSteel work to make the on-site work of our partners and their trades as easy and seamless as possible. But where did this endless quest to make things easier for others come from? Well, there are a few influencing factors at play…

No, it’s not just a sales pitch. Tradies love working with AusSteel and our legendary framing systems. Why? Well, for a few reasons. Let’s take a look…

Behind every successful company is a set of core values earnestly embraced by all stakeholders, and AusSteel is no different. For AusSteel, those core values look like this…

An insight into the purpose, passion, and values behind the AusSteel brand with AusSteel COO, Lewis Onley. Plus some timeless advice for those looking to build their dream home…

It is a common misconception that steel framing increases electrical hazards to builders and occupants. In reality, steel-framed homes are usually a safer option than the alternatives. Let us explain…

Building a home can be a very costly process. Thankfully, building your home with a steel framing system can afford you some savings which don’t put your investment – or your home’s integrity – in jeopardy.

When considering the longevity of your home, it’s worth investing some time in thinking about how you’ll best protect the crucial foundation of your home: your framing system. When it comes to the risk of termites and borers infesting and eating away at your home’s frame, the logical choice is to minimise the risk as much as possible.

It’s common knowledge amongst new home builders that steel framing is the most logical choice when it comes to a strong, non-combustible framing choice. But did you know that steel framing is also considered the best choice for building in flood zones?

In a time where consumers are downsizing and minimising in a bid to lessen their eco footprint or to cut back on the cost of living, Tiny Homes are more popular than ever. You may be wondering, can I build my Tiny Home with a steel framing system? The short answer is YES. And we think you should. Here’s why…

In Australia, bushfires are a part of life but not one that should be taken lightly. While building with steel doesn’t make your structure “fire proof” it can most definitely increase the fire resistance of your home or business premises.

If this is not your first visit to our blog, you’ll know that we’ve discussed the many benefits of steel framing for both residential and commercial construction before; sustainability, durability and design flexibility being amongst the top benefits of building with light gauge steel. However, today we consider even more reasons why building with steel is better than alternatives, and how these benefit all major parties in the design and build processes.

According to analysts, the global light gauge steel framing market is projected to grow to an approximate value of $52.8 billion AUD over the next five years, signalling a strong Compound Annual Growth Rate of 4% in that same period.

With light gauge steel playing a substantial role in Australian infrastructure, it may be encouraging for consumers to know that the processes of production, manufacturing and application of light gauge steel in manufacturing and construction are subject to compliance with design standards.

The Australian steel industry is a formidable one; the integrated supply chain of over 300 suppliers in Australia holds somewhere around two million tonnes of combined inventory at any given time. It is no wonder that our country is acknowledged as a global leader in steel manufacturing.

In Australia today – and indeed across the world – light gauge steel framing is increasingly becoming the ideal framing system for all kinds of construction projects. When it comes to residential builds, we believe that cold formed light gauge steel is the ultimate choice.

The world of steel is constantly evolving – with innovation at the forefront of the industry. When it comes to cold-formed light gauge steel – the steel we work with here at AusSteel – focus areas for research on innovation are abundant.

In recent years there has been some heated debate over whether or not steel can really be considered a sustainable building material…

We love steel – there’s no denying it. Here are some facts you may not know about our favourite alloy-carbon duo…

Waste

Winner: Steel

Why: Steel frames and trusses are very precisely designed and manufactured, meaning less waste is

generated in this stage of the process. Whereas naturally occurring imperfections in timber can

render a certain amount of the manufactured timber as unworkable. To add to this, steel can be

recycled over and over again without compromising its properties!

Did you know steel framing has been part of the Australian building industry for 50 years?

Post-war conception

In the late 1940s, demand for housing was at an all-time high despite post-war materials shortages.

As a result, a steel wall framing system called Econosteel was conceived and then installed in over

300 houses in Canberra, ACT.